Noise Control

Noise at work can lead to serious health risks for both your workers and the wider public. Excessive noise can make warnings harder to hear, interfere with communications and lead to a range of long-term medical conditions.

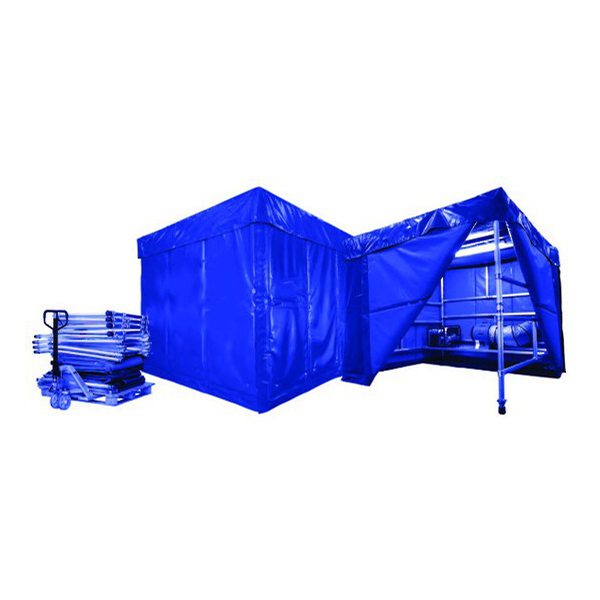

Pneumatic drills, power tools, breakers and generators can easily breach noise limits on site. Ultimate Solutions offer Sound Buffer curtains, acoustic barriers, pile driver sound absorbing cloak, cutting stations and noise enclosures to reduce noise on construction sites. Many of our noise reduction products are available for hire or purchase.

To control hazardous noise, you must ensure that a seamless barrier is placed within the sound path between the source and potential receivers (those on site and nearby). The barrier should be positioned as close to the noise source as possible. This will maximise the amount of sound adsorbed and create a noise shadow. Therefore, persons and properties within the noise shadow will be sufficiently protected from the most intense, direct noise waves. A seamless barrier also prevents any sound waves travelling through gaps. Noise is like water; it does not matter how small a gap may be, noise will leak through. By ensuring that your noise barriers are seamless, you prevent a significant amount of noise escaping. Sound adsorption is an essential component of effective noise control. Sound waves can “bounce” off reflective surfaces, such as the outsides of buildings and concrete. Sound reflection could therefore be used as a very basic form of acoustic control, but the sound waves have to go somewhere. As a result of reflection, they could bounce around site or into nearby areas populated by residents, workers and commuters. By simply redirecting the sound waves you are ultimately exposing people to hazardous noise. Therefore, barriers made of high-quality adsorbent material are vital to effective noise control. Employing seamless adsorbent barriers allows the sound waves to be absorbed into the material, reducing the levels of hazardous noise from the work area. When working in live, busy areas where strict noise regulations are in place, adsorbent noise barriers are the ideal solution.

- CHALLENGE:Machinery such as breakers, pneumatic tools, generators, and demolition equipment can easily breach the maximum noise levels de ned by HSE. Contractors, therefore, need to install noise barriers to ensure that they are not only protecting other works on-site but also protecting surrounding businesses and members of the public.

- RISK: Failure to provide adequate noise control will not only land you in hot water with the HSE and local authorities, but negligence could also leave you open to lawsuits presented by those working or living within close proximity. Claims could arise for, hearing loss, tinnitus, disturbed sleep, mental health issues, impaired memory, reduced quality of life and loss of earning.

- SOLUTION:

Ultimate Solutions believes that e ffective noise control can be managed in three easy steps:

Capture the hazard – Position the acoustic barrier close to the noise source (fully enclosing it if possible) to maximise the acoustic shadow area.

Contain the hazard – Block the line of sight by ensuring the noise barrier is seamless. You may wish to consider whether an enclosure would be more suitable for fully containing the noise.Control the hazard – Use high quality noise barriers, with high sound attenuation, to absorb excessive noise. Screening reflective surfaces like walls may also help to reduce noise bouncing the sound over the barriers.